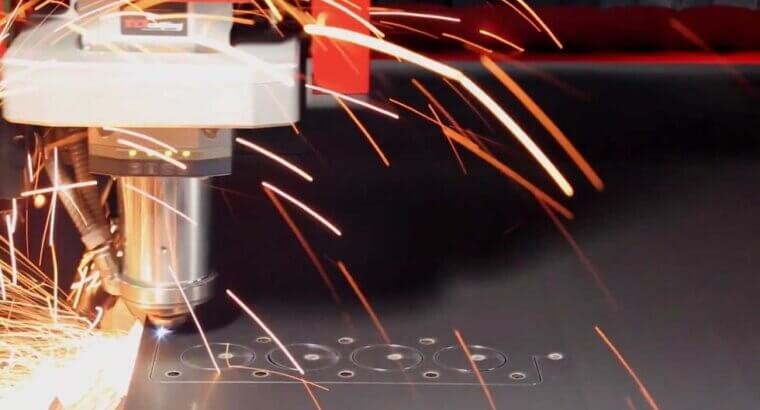

Energy Cut Gas Mix 2.0 is the technological development of TCI Cutting that reduces gas consumption by up to 70%, by efficiently and automated combining the oxygen and nitrogen gases used in laser cutting of carbon steel parts.

Cutting with fiber laser technology at high powers represents a very high monthly bill for factories, a cost that is greatly reduced thanks to Energy Cut Gas Mix 2.0. Another of its benefits is that it increases cutting speed up to 30% depending on the power used, which speeds up production and improves delivery times to customers. Additionally, this solution improves cut quality and reduces burr by up to 70%, eliminating the subsequent deburring process.

On the other hand, this development eliminates any possible overheating of the sheet metal, which makes the work of the operators easier and guarantees perfect finishes.

TCI Cutting’s team of technological development experts carries out personalized studies for clients at the Guadassuar factory (Valencia) with a highly personalized approach according to the company’s objectives and needs. Energy Cut Gas Mix 2.0 is an option that can be integrated into all TCI cutting laser cutting machines.